Valves

Specifications:

1.Nominal diameter: 200-1800mm

2.Nominal pressure: 0.6-10.0 MPa

3.Flow capacity: 0-86400 m3/h

4.Technical characteristics:

①Submerged layout

②Excellent anti-cavitation performance3. Large decompression ratio of 20:1

③The linear adjustment

④Flow adjustment and pressure adjustment

⑤High-precision adjustment valves

5. Driving mode: manual,electrical, hydraulic

6. Typical applications: Pressure of pipeline. Accurate adjustment and control of flow. Discharge of the dam. Ecological discharge control of bypass unit.

1.Nominal diameter: 200-1800mm

2.Nominal pressure: 0.6-10.0 MPa

3.Flow capacity: 0-86400 m3/h

4.Technical characteristics:

①Submerged layout

②Excellent anti-cavitation performance3. Large decompression ratio of 20:1

③The linear adjustment

④Flow adjustment and pressure adjustment

⑤High-precision adjustment valves

5. Driving mode: manual,electrical, hydraulic

6. Typical applications: Pressure of pipeline. Accurate adjustment and control of flow. Discharge of the dam. Ecological discharge control of bypass unit.

Specifications:

1.Nominal diameter: 300-2000 mm

2.Nominal pressure: 2.5-10MPa

3.Technical characteristics:

①Electrical and hydraulic pressure all in one.

②Switching on by hydraulic and switching off by heavy hammer. Safe and reliable.

③Hydraulic driving. Double-metal sealing.

④Compact structure for saving space.

⑤Meet the requirements of "Unattended, Few people attended".

4.Driving mode: Hydraulic.

5.Typical applications: Turbine inlet valve.

1.Nominal diameter: 300-2000 mm

2.Nominal pressure: 2.5-10MPa

3.Technical characteristics:

①Electrical and hydraulic pressure all in one.

②Switching on by hydraulic and switching off by heavy hammer. Safe and reliable.

③Hydraulic driving. Double-metal sealing.

④Compact structure for saving space.

⑤Meet the requirements of "Unattended, Few people attended".

4.Driving mode: Hydraulic.

5.Typical applications: Turbine inlet valve.

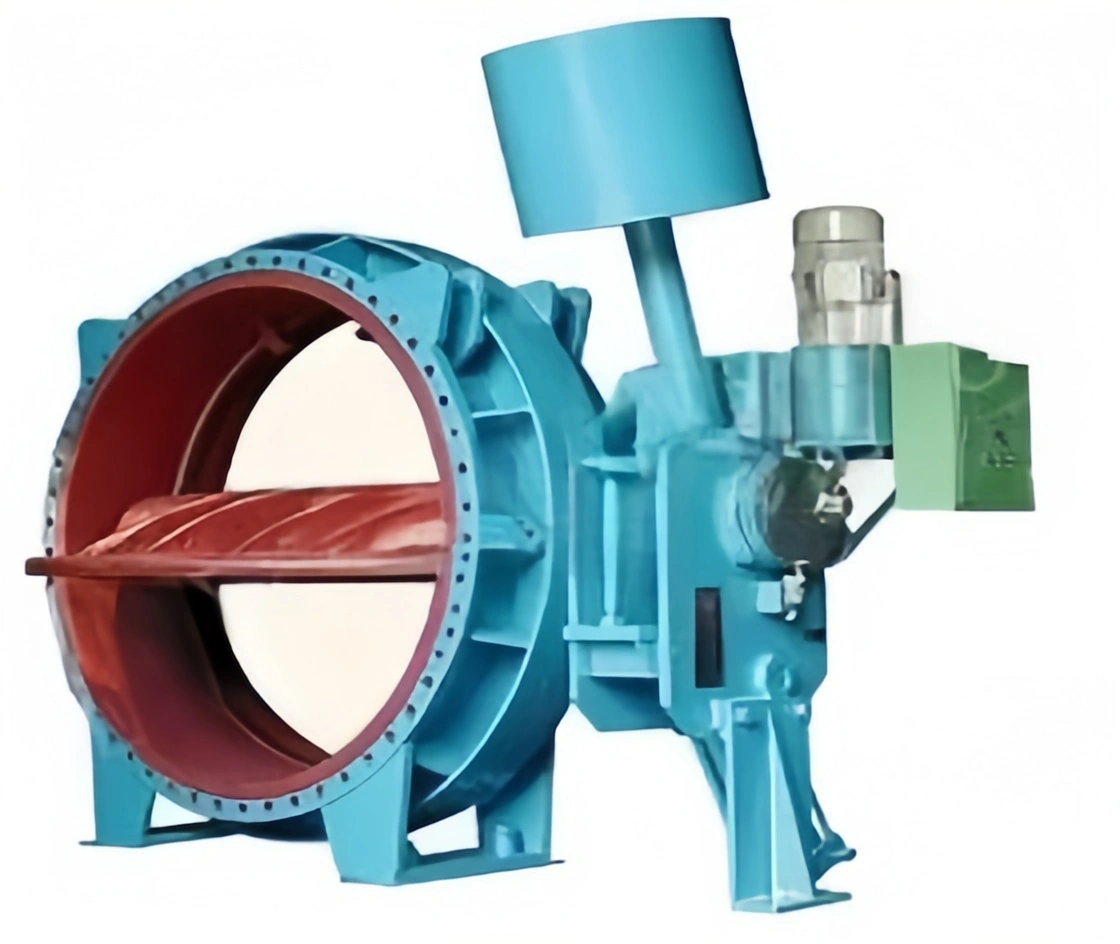

Specifications:

1.Nominal diameter: 100-3000 mm.

2.Nominal pressure: 0.6-2.5MPa.

3.Technical characteristics:

①Simple in structure and weighs light. Flexible for opening and closing.

②Eccentric structure for reducing the friction of sealing ring.

③Reasonable design of sealing structure.

④Apply to different medium and temperature.

⑤Vertical or horizontal installation.

⑥Easy assembly and disassembly, convenient for maintenance.

4.Driving mode: manual, electrical.

5.Typical applications: Water and water resource projects; Environmental protection; Municipal facilities; Electricity and utilities; Construction industry, Petrochemical industry; Iron and steel metallurgy; Paper industry.

1.Nominal diameter: 100-3000 mm.

2.Nominal pressure: 0.6-2.5MPa.

3.Technical characteristics:

①Simple in structure and weighs light. Flexible for opening and closing.

②Eccentric structure for reducing the friction of sealing ring.

③Reasonable design of sealing structure.

④Apply to different medium and temperature.

⑤Vertical or horizontal installation.

⑥Easy assembly and disassembly, convenient for maintenance.

4.Driving mode: manual, electrical.

5.Typical applications: Water and water resource projects; Environmental protection; Municipal facilities; Electricity and utilities; Construction industry, Petrochemical industry; Iron and steel metallurgy; Paper industry.

Specifications:

1.Nominal diameter: 1000-3000 mm

2.Nominal pressure: 0.25 -1.0MPa

3.Technical characteristics:

①The valve can cut-off the medium from two directions, and can realize reliable seal without any leakage from two directions.

②Manual or electric operation.

③With double disc structure and double seals, seals are reliable.

④Optional electric heating protection devices such as valve operation.

⑤Convenient to replace the seals

4. Driving mode: manual, electric.

5. Typical applications: Air cooled condenser system of air cooling power generation unit in thermal power stations.

1.Nominal diameter: 1000-3000 mm

2.Nominal pressure: 0.25 -1.0MPa

3.Technical characteristics:

①The valve can cut-off the medium from two directions, and can realize reliable seal without any leakage from two directions.

②Manual or electric operation.

③With double disc structure and double seals, seals are reliable.

④Optional electric heating protection devices such as valve operation.

⑤Convenient to replace the seals

4. Driving mode: manual, electric.

5. Typical applications: Air cooled condenser system of air cooling power generation unit in thermal power stations.

Specifications:

1.Nominal diameter: 200-1800mm

2.Nominal pressure: 0.6-4.0MPa

3.Technical characteristics:

①Approximate linear flow characteristics

②Excellent resistance to cavitation

③Small operating torque

④0utlet throttling parts are easy to replace

4.Driving mode: Manual, electric, hydrodynamic

5.Typical application: On-line pipeline regulation

1.Nominal diameter: 200-1800mm

2.Nominal pressure: 0.6-4.0MPa

3.Technical characteristics:

①Approximate linear flow characteristics

②Excellent resistance to cavitation

③Small operating torque

④0utlet throttling parts are easy to replace

4.Driving mode: Manual, electric, hydrodynamic

5.Typical application: On-line pipeline regulation

Model B10 Sleeve Valve

1.Nominal diameter: 200-1800mm

2.Nominal pressure: 0.6-10.0 MPA

3.Through-flow capacity: 086400 m/h

4.Technical characteristics:

①On-line layout

②Excellent resistance to cavitation

③Large pressure reduction ratio(20:1)

④Linear regulation

⑤Flow regulation, pressure regulation

⑥High-end precision control valve

5. Driving mode: Pilot(water pressure), manual, electric, hydraulic typical.

6. Application: Precise regulation and control of pipeline pressure and flow.

1.Nominal diameter: 200-1800mm

2.Nominal pressure: 0.6-10.0 MPA

3.Through-flow capacity: 086400 m/h

4.Technical characteristics:

①On-line layout

②Excellent resistance to cavitation

③Large pressure reduction ratio(20:1)

④Linear regulation

⑤Flow regulation, pressure regulation

⑥High-end precision control valve

5. Driving mode: Pilot(water pressure), manual, electric, hydraulic typical.

6. Application: Precise regulation and control of pipeline pressure and flow.

Specifications:

1.Nominal diameter: 80-500mm

2.Nominal pressure: l.0-10 MPa

3.Technical characteristics:

①Simple structure and reliable performance

②Reliable sealing

③Large intake, exhaust capacity and air displacement.

4.Typical applications: pipeline intake and exhaust, Air admission and evacuation of pipeline.

1.Nominal diameter: 80-500mm

2.Nominal pressure: l.0-10 MPa

3.Technical characteristics:

①Simple structure and reliable performance

②Reliable sealing

③Large intake, exhaust capacity and air displacement.

4.Typical applications: pipeline intake and exhaust, Air admission and evacuation of pipeline.

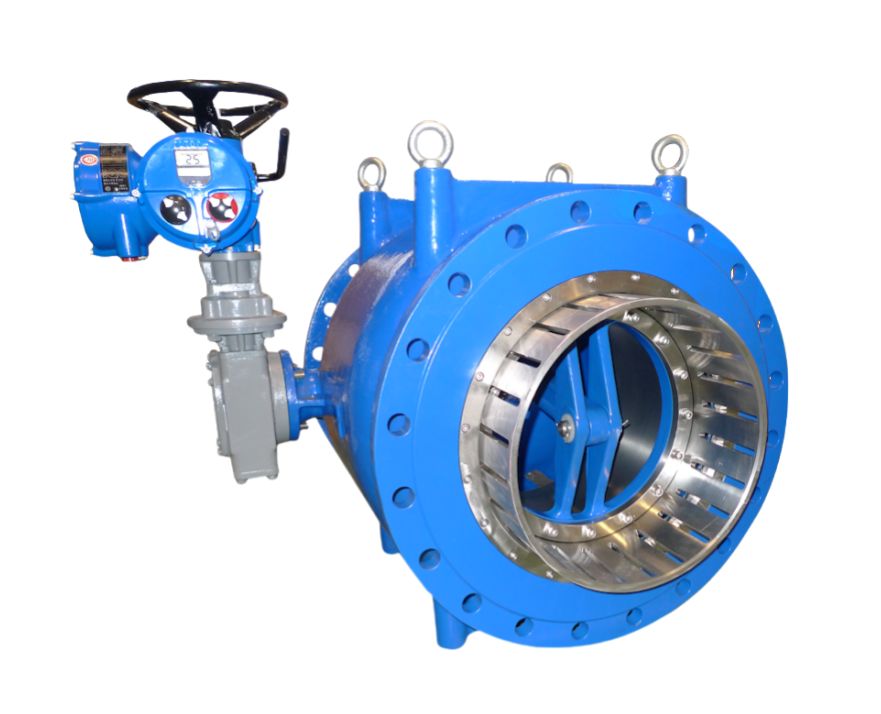

Energy Storage Tank Type Hydraulically Controlled Butterfly Valve

Materials of Valve Parts.

1.Body: Ductile iron. Carbon steel.

2.Disc: Ductile iron. Carbon steel.

3.Shaft: Carbon steel. Stainless steel.

4.Sealing ring on valve body: Stainless steel.

5.Sealing ring on valve disc: quality rubber. Stainless steel.

Specifications:

1.DN range: DN300-DN6000.

2.PN range: PN6-PN40

3.Applicable temperature: ≤80℃

4.Applicable medium: water. Seawater. Mud and sand water.

1.DN range: DN300-DN6000.

2.PN range: PN6-PN40

3.Applicable temperature: ≤80℃

4.Applicable medium: water. Seawater. Mud and sand water.

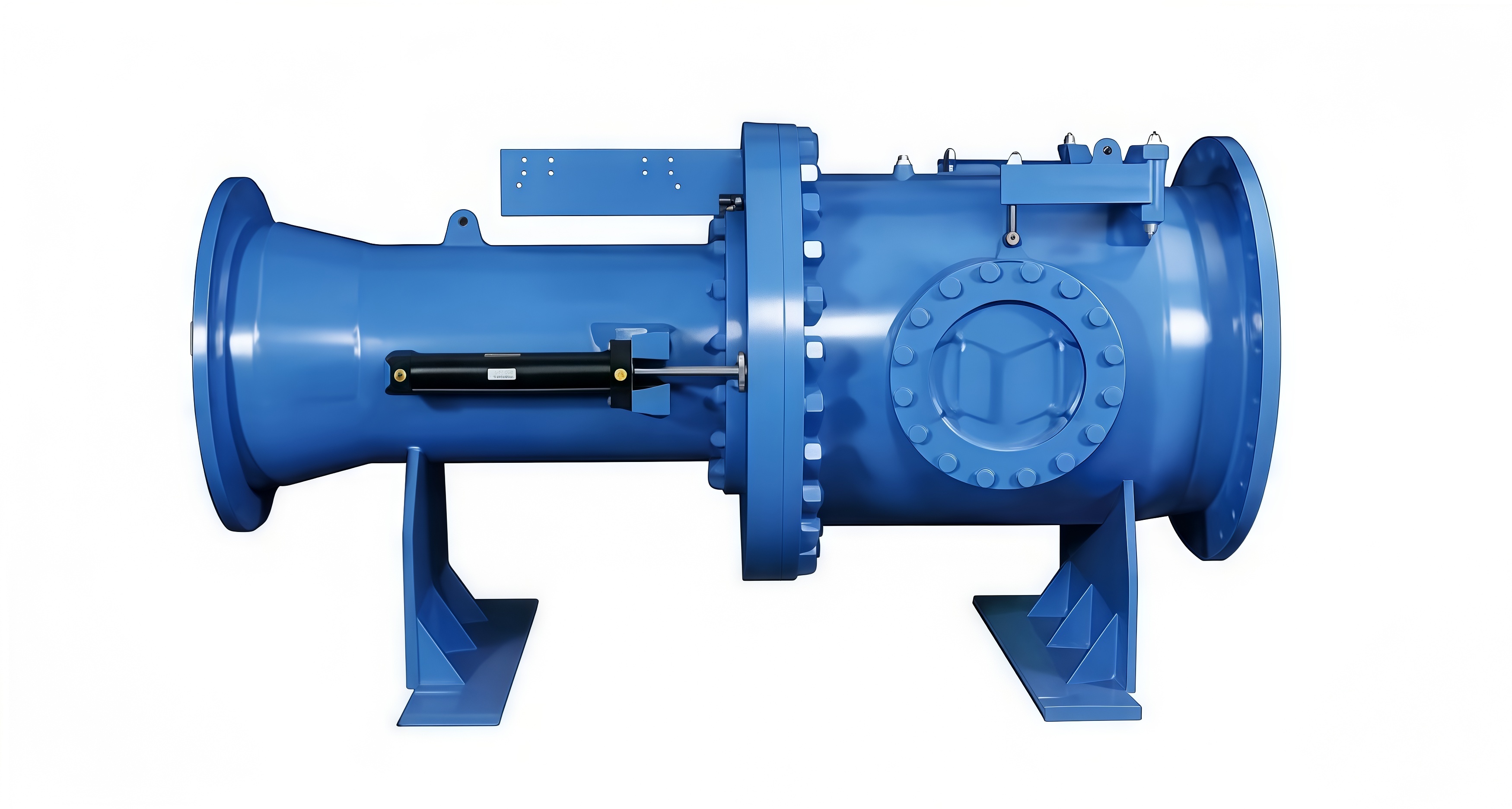

Hydraulic Controlled Butterfly Valve for Pumping Station

Materials of Valve Parts.

1.Body: Ductile iron. Carbon steel.

2.Disc: Ductile iron. Carbon steel.

3.Shaft: Carbon steel. Stainless steel.

4.Sealing ring on valve body: Stainless steel.

5.Sealing ring on valve disc: quality rubber. Stainless steel.

Specifications:

1.DN range: DN300-DN6000.

2.PN range: PN6-PN40

3.Applicable temperature: ≤80℃

Applicable medium: water. Seawater. Mud and sand water.

1.Body: Ductile iron. Carbon steel.

2.Disc: Ductile iron. Carbon steel.

3.Shaft: Carbon steel. Stainless steel.

4.Sealing ring on valve body: Stainless steel.

5.Sealing ring on valve disc: quality rubber. Stainless steel.

Specifications:

1.DN range: DN300-DN6000.

2.PN range: PN6-PN40

3.Applicable temperature: ≤80℃

Applicable medium: water. Seawater. Mud and sand water.