Pumps

Stainless Steel Screw PumpThreaded Interface

Pressure:0~1.2Mpa(0~348 psi)

Various connection methods(flange,SMS,Tri-Clamp)

Suitable for conveying various materials in food,medicine,cosmeticsand bioengineering with clean and hygienic requirements.The flow-passing surface is polished,has no dead spots and is easy to clean.

Large Hopper Progressive Cavity Pump InBlock Construction

Pressure:0~4.8Mpa(0~700 psi)

Stable structure,adaptable to harsh working conditions,

transporting media with high viscosity and poor fluidity.

Large-taperforced feeding chamber and special connectingrod

design provide stronger propulsion force and optimizematerial transportation.

Industrial Screw Pump Bearing Type

Pressure:0~2.4Mpa(0~348 psi)

Suitable for various media with high viscosity and solidparticles

With bearing seat,it can reduce the axial force of the pump,increaseits senvice life and withstand greater pressure.

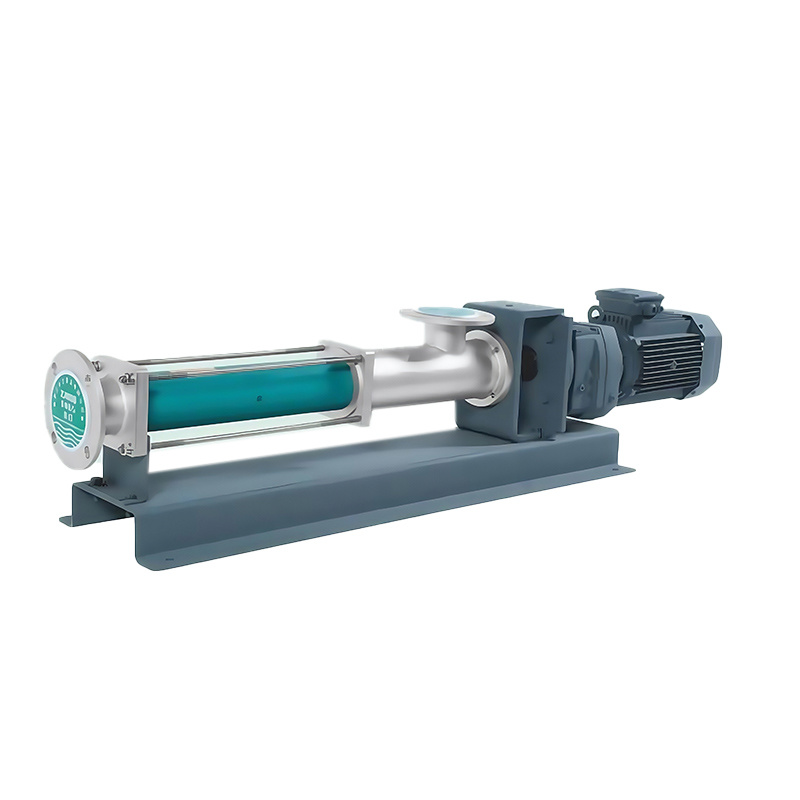

Industrial Grade Stainless SteelScrew Pump

Pressure:0~2.4Mpa(0~348 psi)

Gentle conveying,no pulsation,smooth operation

Suitable for various media with high viscosity and

solid particles

Industrial Cast Iron Screw Pump Direct Connection Type

Pressure:0~2.4Mpa(0~348 psi)

Suitable for various media with high viscosity and solid particles

With bearing seat,it can reduce the axial force of the pump,increaseits senvice life and withstand greater pressure.

Immersibie VerticalProgressive Cavity PumpWith Bracket or Flange

Pressure:0-~2.4Mpa(0~348psi)

It adopts trumpet-shaped stator and has strong self-primingability.

Suitable for pumping materials from barrels,tanks,boxes andtroughs,especially in places with narrow space and dangerousculverts.

Hygienic Food Grade Progressive

Pressure:0~2.4Mpa(0~348 psi)

Various connection methods(flange,SMS,Tri-Clamp)

Suitable for conveying various materials in food,medicine,cosmeticsand bioengineering with clean

and hygienic requirements.The flow

-passing surface is polished,has no dead spots and is easy to clean.

Hopper Progressive Cavity Pump InBlock Construction

Pressure:0~2.4Mpa(0~348 psi)

Rectangular suction hopper with adjustable

size,with/withoutauxiliary feeding chamber.

The connecting rod has a feeding blade to forcefully

transporthigh viscosity and high solid content media.

Cast Iron Screw PumpThreaded Interface

Pressure:0~2.4 Mpa(0~348 psi)

Measurement error±1%

Suitable for conveying viscous materials with asmall flow

rate,and can be used for chemical metering with a speed

regulating device.

KQWH Series Single Stage Horizontal Chemical Pump

Head: 2.8-129m

Motor power: 0.12-90kW

Speed: 1480r/min or 2960r/min

Maximum working pressure: ≤1.6MPa

Medium temperature: -10℃~80℃

Head: 9-306m

Inlet and outlet diameters: 150-600mm

Liquid Temperature: ≤80℃

Ambient temperature typically: ≤40℃

Rotating speed: 740, 990, 1480 and 2960r/min

KQL Direct-coupled in-line Single Stage Vertical Centrifugal Pump

Head: Max 127m

Liquid Temperature: -10 ~80℃ 80~120℃

Ambient temperature typically: ≤40℃

Rotating speed: 980, 1480 and 2960r/min