Split Type Desuperheating Decompression Control Valve

keyword:

Valve

Split Type Desuperheating Decompression Control Valve

Split Type Desuperheating Decompression Control Valve (Model TYP 800)

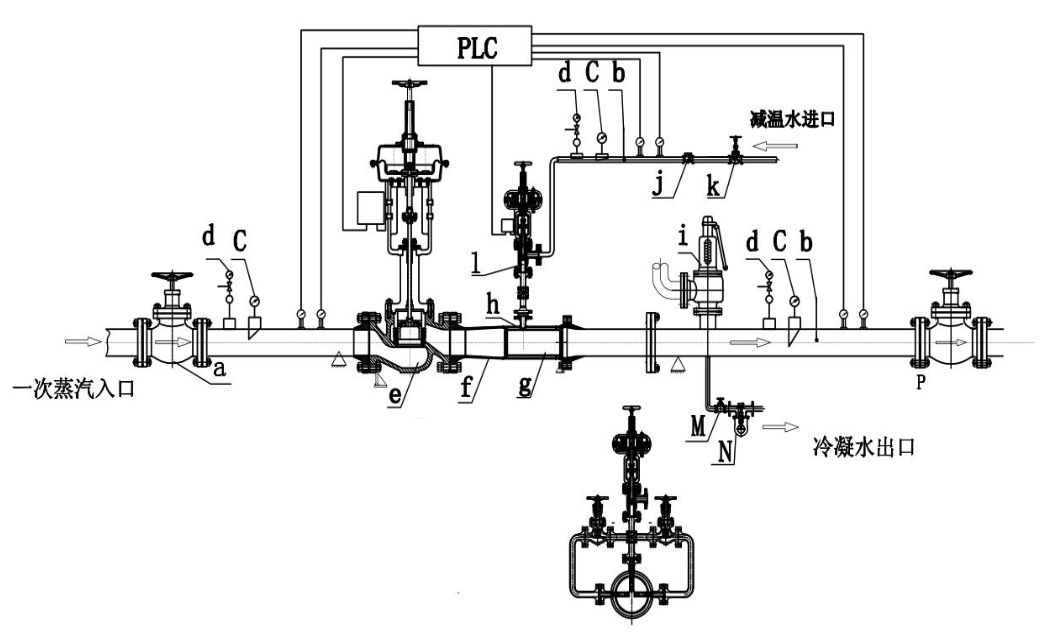

TYP800 series steam is suitable for the industrial process of medium pressure steam the temperature and pressure-releasing valve control. The series control valve in line with the requirements of DIN and ANSI standards, can reduce the steam pressure and temperature at the same time, especially suitable for medium voltage, low pressure steam generation in the power plant industrial area, such as process adjustment valve steam cycle.

Key features:

The pressure reducing system and the desuperheating system operate independently, primarily designed for harsh operating conditions such as high temperature and high pressure. This valve prevents desuperheating water washing against internal parts of valve body.

It is also suitable for applications where superheated steam needs to be reduced to saturated steam. Given the relatively low steam flow velocity in such cases, an annular baffle-type nozzle mechanism is employed to ensure thorough atomization of the desuperheating water, thereby achieving highly effective temperature reduction.

Main specifications:

- Size: DN50-DN500mm.

- Nominal pressure: PN0.6-PN10MPa.

- Body: Straight through, Have a casting or forged steel parts.

- Connection: Flange, weld.

- Adopt structure of two-seat pressure-reducing valve, balanced valve core, the unbalanced force is small, the adjusting range is big, the movement is smooth, no jam phenomenon.

- Desuperheating system adopts the annular baffle-type nozzle spray designed by Germany technology to cool, achieving the effect of atomized rapidly.

- Valve core, valve cage, nozzle is convenient to disassemble and install, and is easy to maintenance.

- Low noise damping board structure.

- The baffle-type structure of Nozzle has a big and smooth circulation way to avoid scale obstruction because of operation for a long time.

- Resistance to cavitation, flashing resistance, cavitation resistance, corrosion resistance, and erosion resistance structure.

- Optional actuators: The spring diaphragm, piston, or electric actuators.

- Advanced digital positioning and control technology.

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

About Our Factory

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

Related Products

There is no relevant data for the time being, please add it backstage!