IJ Chemical Process Pump

keyword:

Valve

IJ Chemical Process Pump

Product Overview

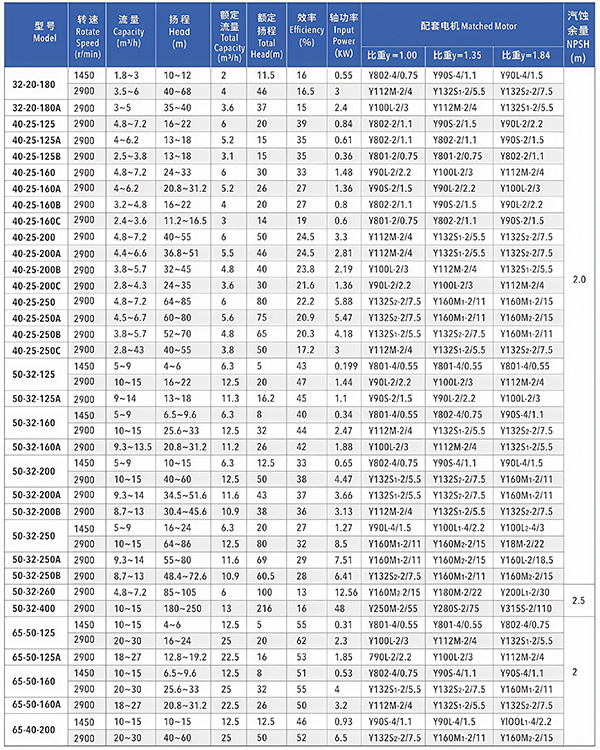

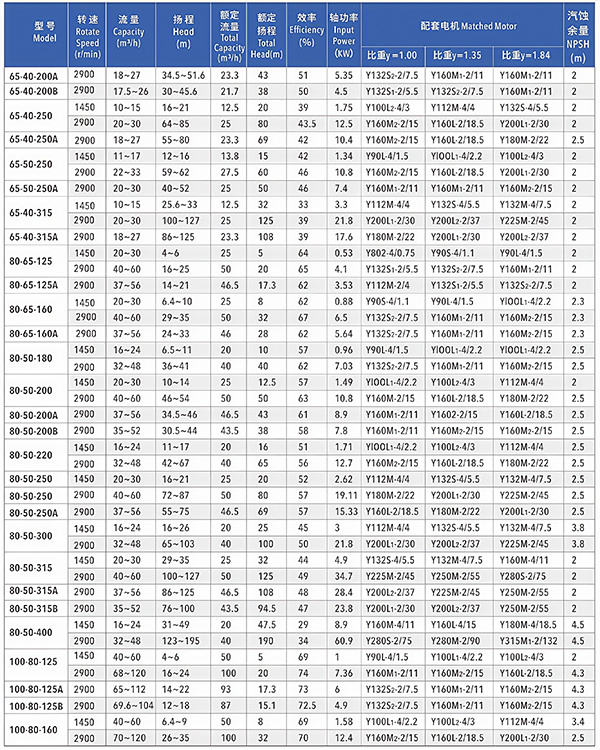

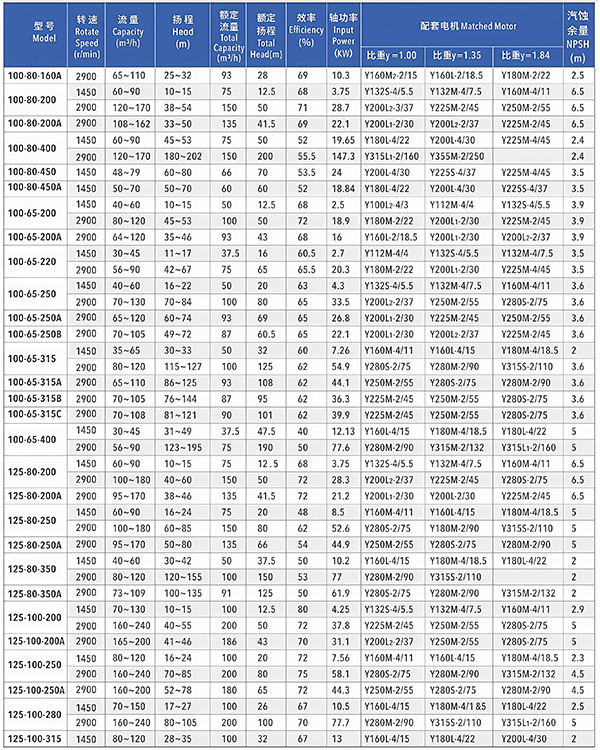

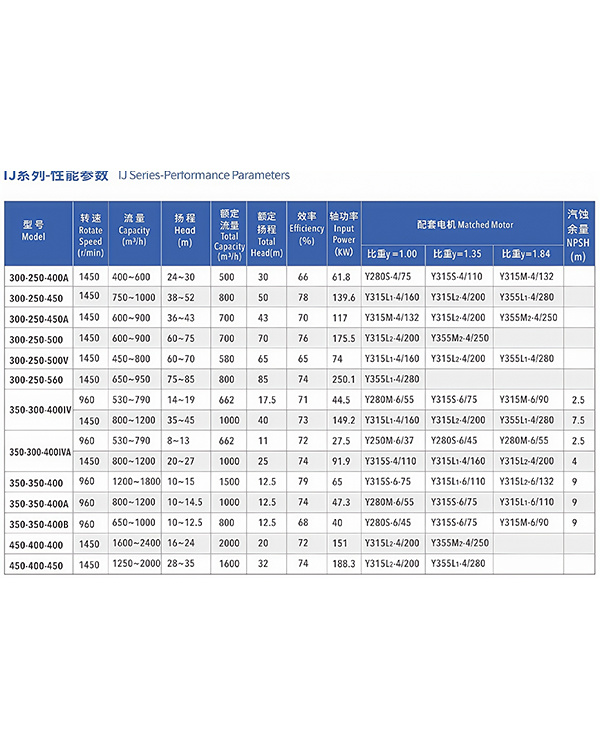

The IJ type chemical process pump is a standardized chemical process pump upgraded and innovated by our company based on the IH pump. The pump is a single-stage single suction cantilever structure, and its performance parameters comply with GB5662-85 (equivalent to IS02858-1975) standard. In terms of design, advanced hydraulic models are adopted, which have high efficiency and are 5% higher than IH pumps, making it an energy-saving product. We drew inspiration from the American ANSI standard in structural design, increased the shaft diameter, shortened the cantilever ratio, eliminated the problem of frequent shaft breakage in IH pumps, improved operational stability, and reduced maintenance and operating costs. Following the American API682 standard, continuous exploration and improvement have been carried out on mechanical seals and sealing chamber structures. The 171 series mechanical seals developed have been successfully used in industries such as soda ash, chlor alkali, salt production, metallurgy, papermaking, environmental protection, as well as in easily crystallized and multi particle working conditions. The sealing form recommended by API610 can also be used. After more than ten years of improvement and expansion, the applicability of IJ pumps has been continuously expanded. Currently, there are more than 100 specifications, covering almost all chemical process applications under pressure of 2.0MPa and temperature of 200 ° C. It is one of the three most widely used chemical process pump series in China, alongside CZ and ZA.

Applied Range

Alkali and inorganic salts: Ammonia salt mother liquor produced by ammonia alkali method and combined alkali method, pure alkali, electrolyte, caustic alkali, chloride and hypochlorite produced by membrane alkali and ion membrane process, sulfide alkali, sulfate, hydrogen peroxide, etc.

Nonferrous metal smelting: electrolyte for electrolyzing copper and nickel, sodium aluminate solution for producing aluminum, acid mist solution for producing cobalt, slurry solution for producing zinc, ammonium aluminate solution for producing alum, acid mist solution and sulfur gland solution for producing gold, etc.

Steel industry: electroplating, pickling, electrophoretic paint, etc.

Acid making industry: hydrochloric acid, nitric acid, sulfuric acid, phosphoric acid, phosphoric acid slurry, acetic acid, etc.

Petrochemical industry: refining, cracking, separation of petroleum, butadiene, alkylbenzene, methanol

Wait.

Synthetic fiber and plastic industry: polyester, dichloromethane, epichlorohydrin, trichloropropane, polyvinyl chloride, dimethylformamide, etc.

Paper industry: pulp cooking solution, green solution, white solution, concentrated black solution, bleaching solution.

Fertilizer industry: urea, ammonium nitrate, ammonium bicarbonate, ammonium chloride, ammonium phosphate, potassium chloride, potassium sulfate, etc.

Fermentation industry: intermediates, lactic acid, citric acid, food additives, beer, various fermentation slurries, etc.

Environmental protection: various chemicals, acidic and alkaline wastewater, etc.

Structural Features of the Pump

The pump body is designed for axial suction and radial discharge. Support feet are cast on the pump body and directly fixed to the base. The pump cover is fixed to the suspension body through a stopper, and the pump body and suspension body clamp the pump cover. Remove the connecting nut between the suspension body and the pump body during maintenance, and the transmission part of the pump can be withdrawn from the pump body without dismantling the inlet and outlet pipelines. For large-sized pumps, there is an intermediate extension joint between the pump coupling and the motor shaft. During maintenance, the motor does not need to move. By removing the intermediate extension joint, the transmission part can exit the pump body. This is an internationally recognized chemical pump structure.

Previous

Next

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

About Our Factory

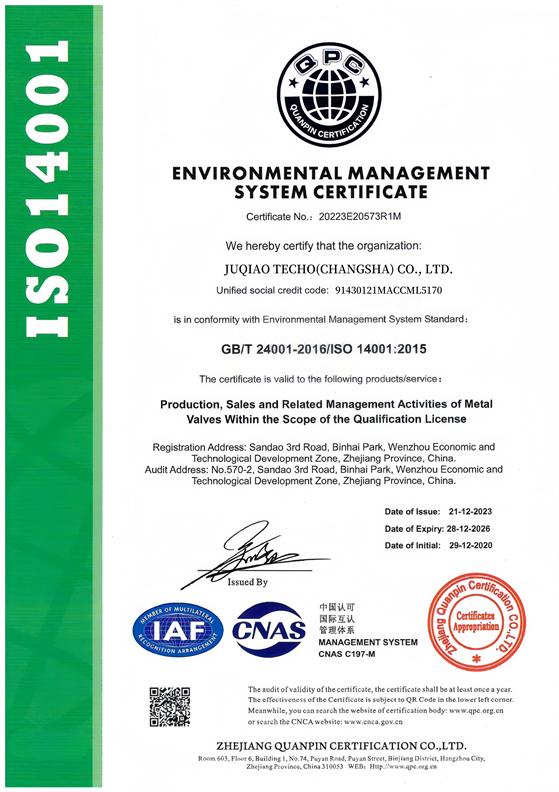

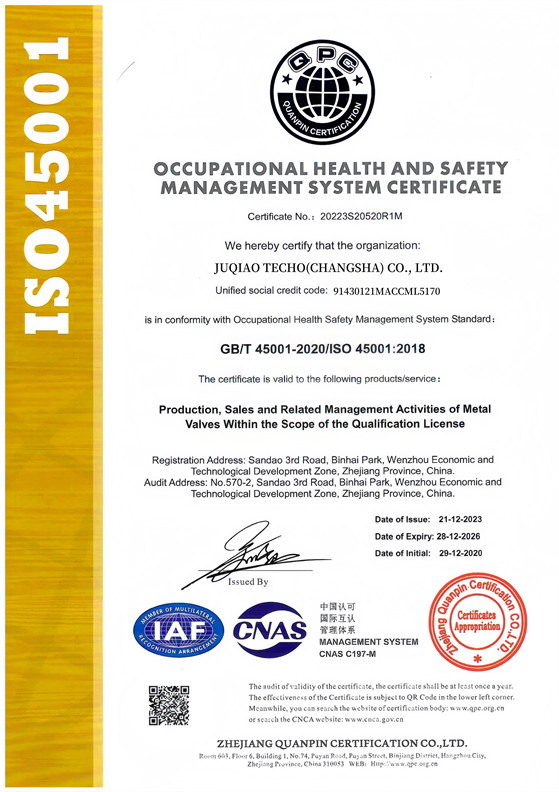

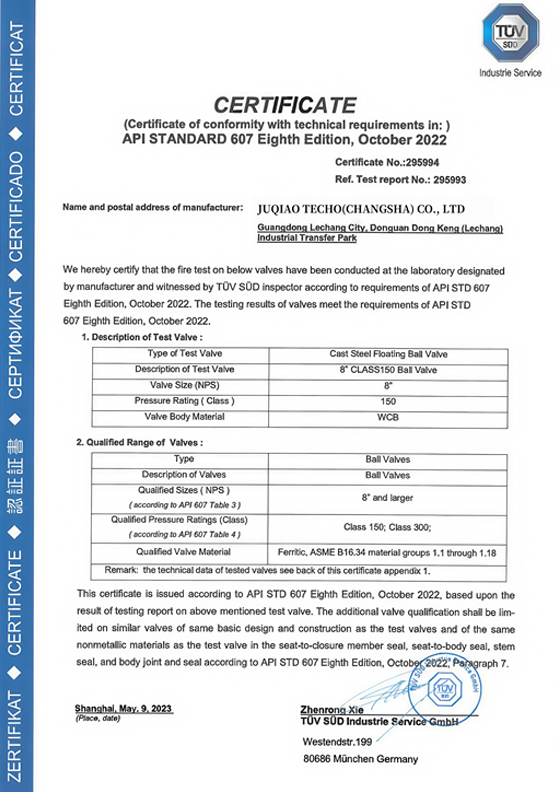

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

Related Products

There is no relevant data for the time being, please add it backstage!