AZ slurry pump

304,321,316L, 310Cu, 0Cr25Ni16 (duplex stainless steel), 20 # alloy, 904L, TA2 (titanium), Ti/Pd (lithium titanium), Ni (nickel) Monel alloy.

keyword:

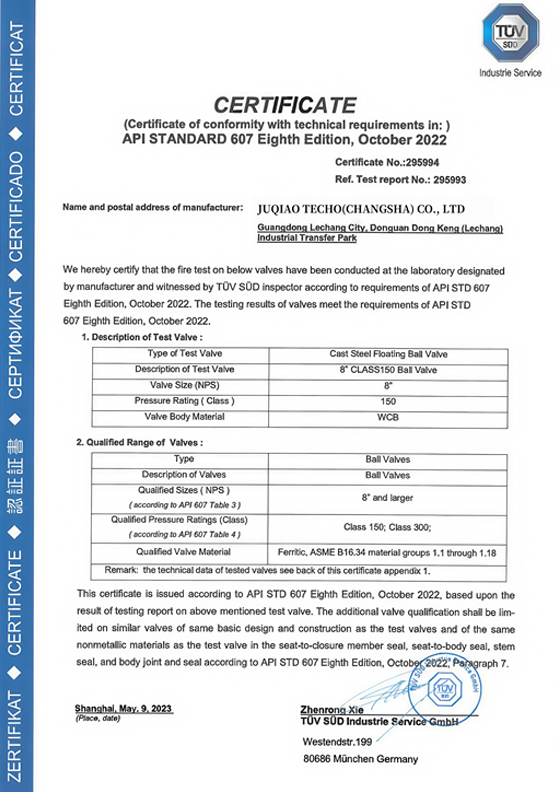

Valve

AZ slurry pump

Product Overview

The AZ series slurry pump is an extension product of HTZ slurry pump, which was successfully designed by our company based on long-term technical accumulation and reference to advanced foreign technology. It is an upgraded product of pump types such as TWZ and ZBJ, with strong fiber and particle passing ability, smooth operation, and easy maintenance. It can transport pulp with a concentration of less than 6% and other pulp with a solid content of less than 30%. Suitable for working environments such as papermaking, metallurgy, salt mining, wastewater treatment, and power plants.

Applied Range

Alkali and inorganic salts: Ammonia salt mother liquor produced by ammonia alkali method and combined alkali method, pure alkali, electrolyte, caustic alkali, chloride and hypochlorite produced by membrane alkali and ion membrane process, sulfide alkali, sulfate, hydrogen peroxide, etc.

Nonferrous metal smelting: electrolyte for electrolyzing copper and nickel, sodium aluminate solution for producing aluminum, acid mist solution for producing cobalt, slurry solution for producing zinc, ammonium aluminate solution for producing alum, acid mist solution and sulfur gland solution for producing gold, etc.

Steel industry: electroplating, pickling, electrophoretic paint, etc.

Acid making industry: hydrochloric acid, nitric acid, sulfuric acid, phosphoric acid, phosphoric acid slurry, acetic acid, etc. Petrochemical industry: refining, cracking, separation of petroleum, butadiene, alkylbenzene, methanol

Synthetic fiber and plastic industry: polyester, dichloromethane, epichlorohydrin, trichloropropane, polyvinyl chloride, dimethylformamide, etc.

Paper industry: pulp cooking solution, green solution, white solution, concentrated black solution, bleaching solution.

Fertilizer industry: urea, ammonium nitrate, ammonium bicarbonate, ammonium chloride, ammonium phosphate, potassium chloride, potassium sulfate, etc.

Fermentation industry: intermediates, lactic acid, citric acid, food additives, beer, various fermentation slurries, etc.

Environmental protection: various chemicals, acidic and alkaline wastewater, etc.

Product Materials

The commonly used materials for overcurrent components in contact with the medium are as follows: 304,321,316L, 310Cu, 0Cr25Ni16 (duplex stainless steel), 20 # alloy, 904L, TA2 (titanium), Ti/Pd (lithium titanium), Ni (nickel) Monel alloy.

Previous

Next

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

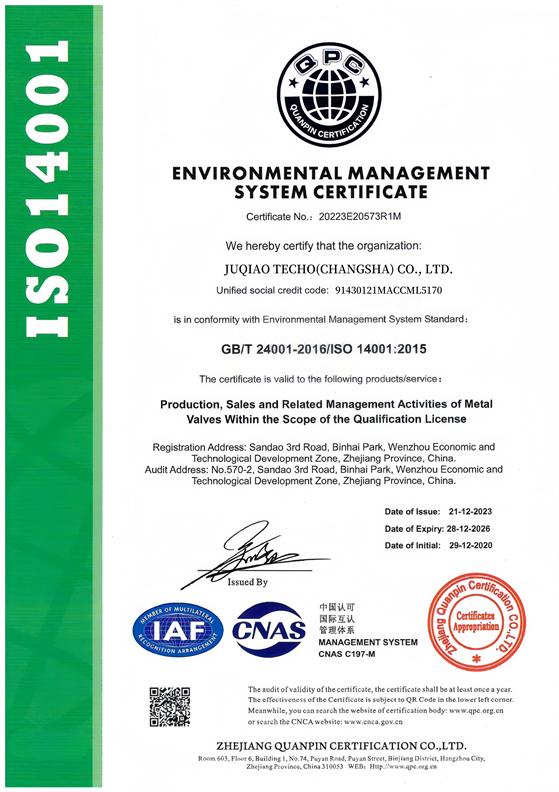

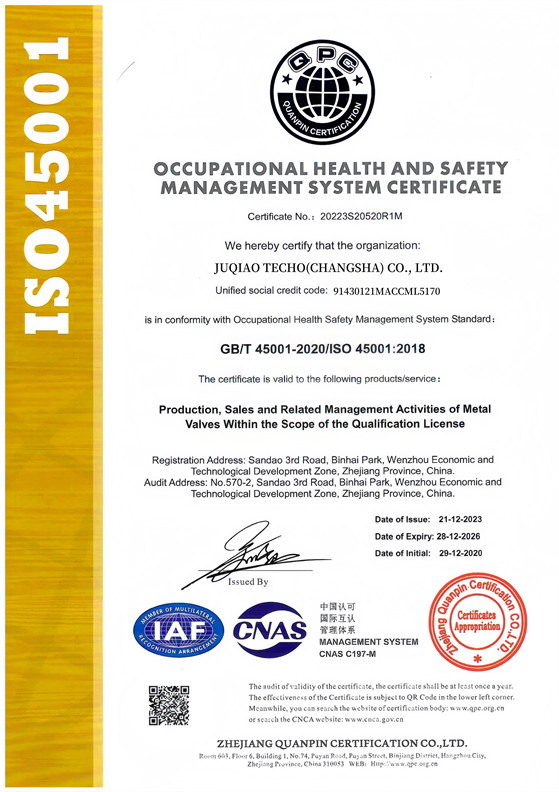

About Our Factory

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

Related Products

There is no relevant data for the time being, please add it backstage!