FQB Fluoroplastic Magnetic Pump

Flow rate: see pump parameters

Head: see pump parameters

Highest altitude: 3000m

keyword:

Valve

FQB Fluoroplastic Magnetic Pump

Product Overview:

FOB type fluoroplastic magnetic pump is a chemical process pump that applies modern magnetic mechanics principles and uses permanent magnets to achieve non-contact indirect transmission. When the motor drives the outer rotor (i.e. outer magnetic steel) assembly to rotate, the magnetic field lines pass through the isolation sleeve and drive the inner rotor (i.e. inner magnetic steel) assembly and impeller to rotate synchronously through the magnetic field. The medium is completely enclosed in the stationary isolation sleeve, thus achieving the goal of leak free pumping of the medium and completely solving the shaft seal leakage of mechanical transmission pumps. It is a new type of industrial pump that is fully sealed, leak free, and pollution-free. FOB type magnetic pump is an ideal pump used in chemical processes to eliminate running, emitting, dripping, and leaking phenomena, eliminate environmental pollution, create "leak free workshops" and "leak free factories", and achieve safe and civilized production.

Applied Range:

This product is widely used in industries such as petrochemicals, acid and alkali production, non-ferrous metal smelting, acid washing processes in automobile manufacturing, rare earth separation, pesticides, dyes, pharmaceuticals, papermaking, electroplating, and radio.

Design Features:

1. Leak proof design and working principle:

Cancelled the shaft seal and used magnetic coupling to indirectly drive, completely eliminating the trouble of dripping and never polluting the usage site. Due to the use of "fluoroplastic alloy" in the overcurrent part of the pump, it can continuously transport corrosive media such as acids, alkalis, and strong oxidants of any concentration

And without any damage. The driving device adopts an active permanent magnet coupling directly installed on the motor shaft, and the pump chamber is completely enclosed. The impeller is indirectly driven to rotate through magnetic coupling. Compact structure, safe and energy-saving.

2. Durable and sturdy pump body structure:

Although the part in contact with the liquid is fluoroplastic, the pump body shell is made of metal material, so the pump body is capable of withstanding the weight of the pipeline and mechanical impact.

Operating Conditions:

Operating temperature: -20 ° C~120 ° C

Flow rate: see pump parameters

Head: see pump parameters

Highest altitude: 3000m

Next

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

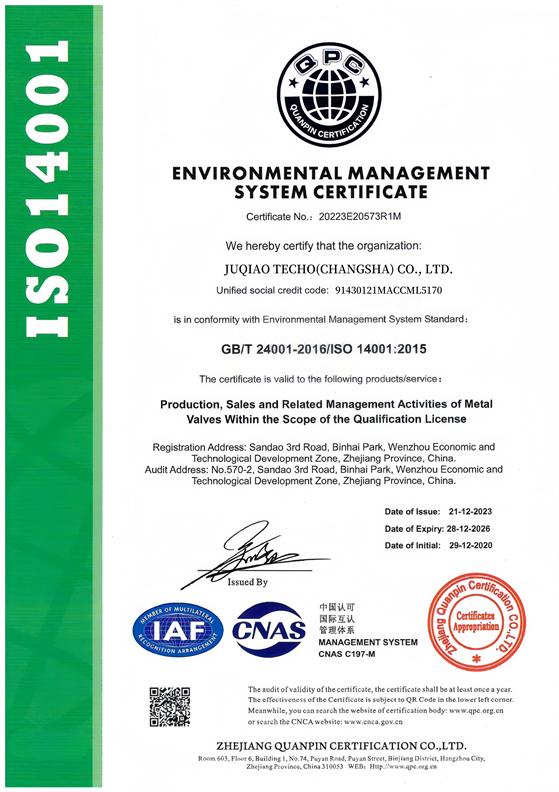

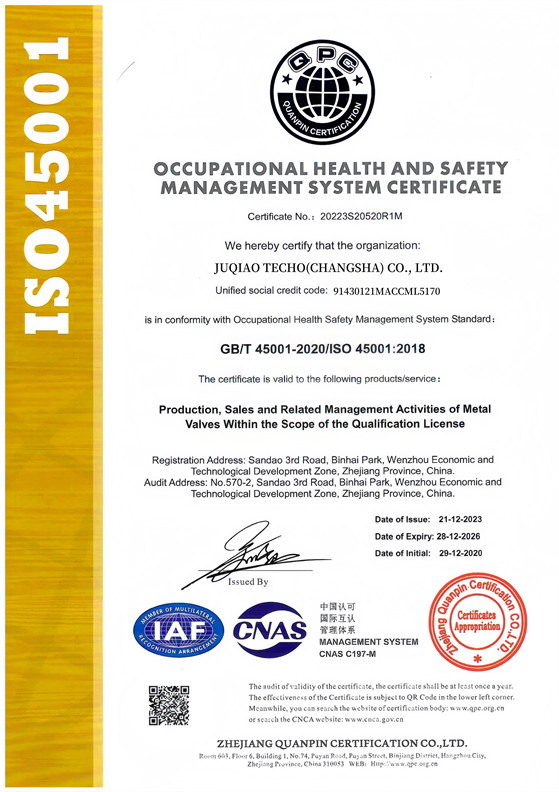

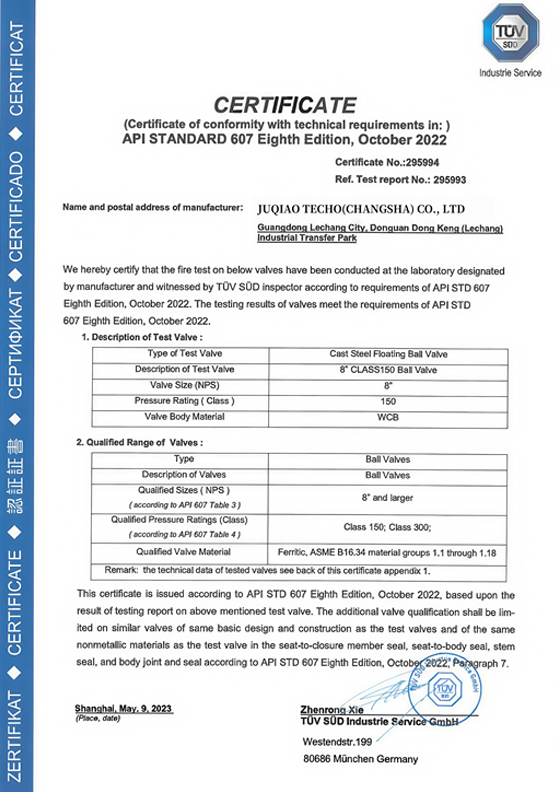

About Our Factory

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

Related Products

There is no relevant data for the time being, please add it backstage!