RUB corrosion resistant and wear resistant mortar pump

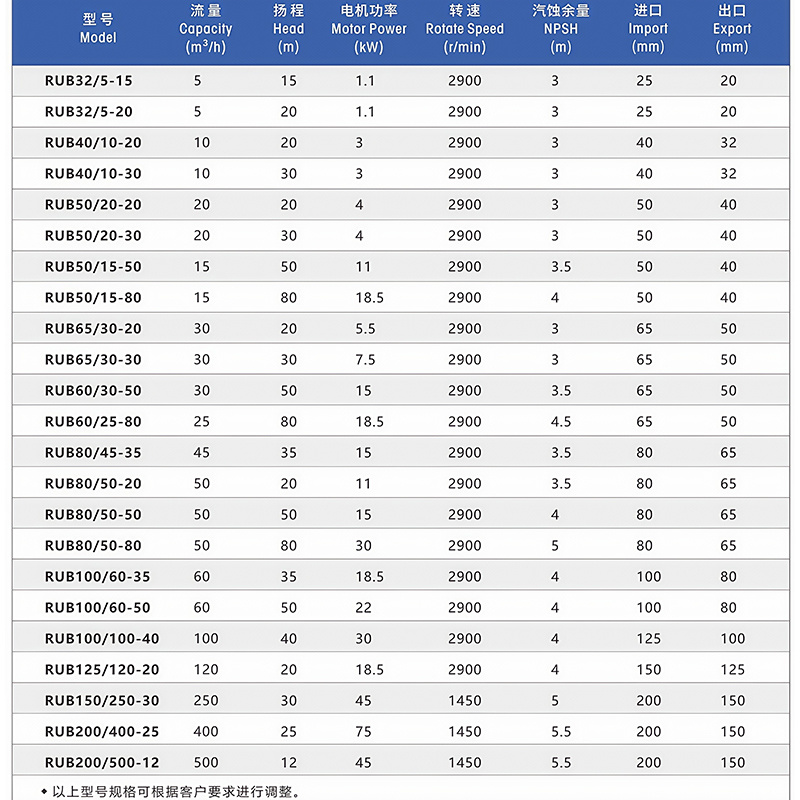

Flow rate: see pump parameters

Head: see pump parameters

Highest altitude: 3000m

keyword:

Valve

RUB corrosion resistant and wear resistant mortar pump

Product Overview:

The RUB corrosion-resistant and wear-resistant mortar pump is a cantilever single-stage single suction centrifugal pump designed and developed specifically for transporting corrosive media containing fine particles. The pump is made of steel lined ultra-high molecular weight polyethylene (UHMW-PE), which is currently the latest generation of corrosion-resistant and wear-resistant engineering plastics for pumps. Its most prominent advantage is that it has the best wear resistance and impact resistance (especially low-temperature impact resistance) among all plastics Creep resistance (resistance to environmental stress cracking) and excellent corrosion resistance.

Design Features:

This pump belongs to the cantilever single-stage single suction centrifugal pump, which adopts steel lined ultra-high molecular weight polyethylene with excellent corrosion resistance and outstanding wear resistance. The RUB corrosion-resistant and frosted slurry pump series products are designed specifically for conveying media with certain corrosiveness and containing fine particles or crystals. They are manufactured using steel lined ultra-high molecular weight polyethylene compression molding technology, which has excellent corrosion resistance and wear resistance. The structural design is a cantilever front opening, and the impeller is semi open (without a front cover plate), enhancing the passage of particles and impurities in the medium quickly through the pump chamber without blockage. The shaft seal is a K-type fluororubber sealing ring with a cooling water jacket, which meets the dual requirements of corrosion resistance and wear resistance. This series of products has received high praise from users in industries such as metal smelting, titanium dioxide, fine chemicals, and fertilizers. In addition, fluoroplastic lining can be used according to customers' special corrosion or temperature resistance requirements, and non-standard models with special flow rates and head can also be customized.

Applied Range:

This product is widely used in liquids such as acids, alkalis, salts, oils, food, beverages, alcoholic beverages, organic solvents, etc., especially suitable for transporting highly corrosive objects containing fine particles.

Operating Conditions:

Operating temperature: -20 ° C~90 ° C

Flow rate: see pump parameters

Head: see pump parameters

Highest altitude: 3000m

Previous

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

About Our Factory

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

Related Products

There is no relevant data for the time being, please add it backstage!