RMC stainless steel magnetic centrifugal pump

Maximum temperature: 100 ° C

Maximum density: 184x10kg/m3

Maximum viscosity: 30x10-6 ㎡/s (liquid without hard particles and fibers). If the system working pressure is greater than 1.6MPa, special design can be carried out, and the maximum system working pressure can reach 15MPA.

keyword:

Valve

RMC stainless steel magnetic centrifugal pump

Product Overview:

Magnetic centrifugal pump (referred to as magnetic pump) is usually composed of an electric motor, a magnetic coupling, and a corrosion-resistant centrifugal pump. Its main feature is the use of a magnetic coupling to transmit power, with no leakage at all. When the motor drives the outer magnetic steel of the magnetic coupling to rotate, the magnetic lines pass through the gap and isolation sleeve, acting on the inner magnetic steel, causing the pump rotor to rotate synchronously with the motor and transmit torque without mechanical contact. At the power input end of the pump shaft, due to the liquid being enclosed in a stationary isolation sleeve without a dynamic seal, it is safe and leak free. The overcurrent components of the pump can be made of corrosion-resistant materials such as 304, 304L, 302, 321, 316, 316L, UB6, CD4MCU, titanium alloy, nickel based alloy, etc. as needed. The IMC series magnetic pump is a new type of completely leak free and corrosion-resistant pump developed by the national joint design team of magnetic pumps. Its technical and economic indicators are comparable to those of similar foreign products in the late 1980s. The type and basic parameters of the RMC series magnetic pump comply with the requirements of TB/T7742-95 "Small Magnetic Transmission Centrifugal Pump" standard.

Applied Range:

The RMC series magnetic pump is suitable for industries such as petroleum, chemical, pharmaceutical, smelting, electroplating, environmental protection, food, film and television printing, water treatment, national defense, etc. It is an ideal equipment for transporting flammable, explosive, volatile, toxic, rare and valuable liquids as well as various corrosion-resistant liquids.

OperatingCondition:

Maximum system pressure for conveying: 1.6MPa

Maximum temperature: 100 ° C

Maximum density: 184x10kg/m3

Maximum viscosity: 30x10-6 ㎡/s (liquid without hard particles and fibers). If the system working pressure is greater than 1.6MPa, special design can be carried out, and the maximum system working pressure can reach 15MPA.

*When the specific gravity and viscosity of the liquid conveyed by the pump are high, the shaft power will increase, so a motor that matches the shaft power must be used.

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

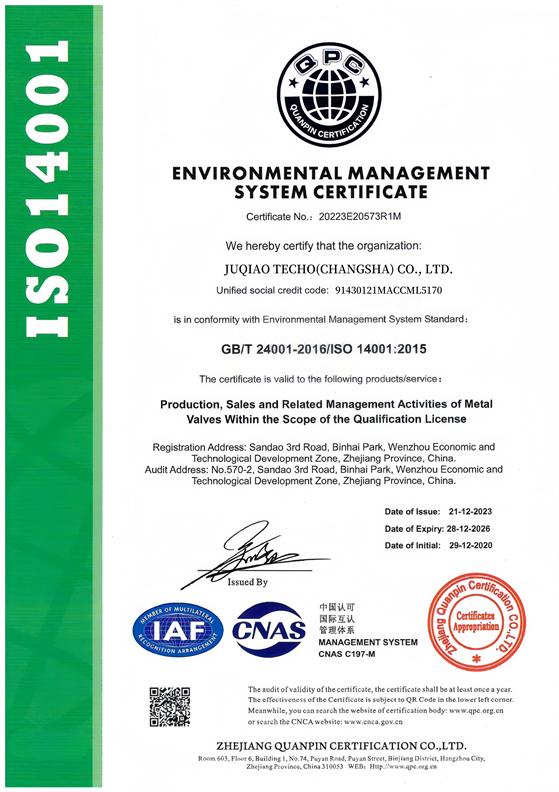

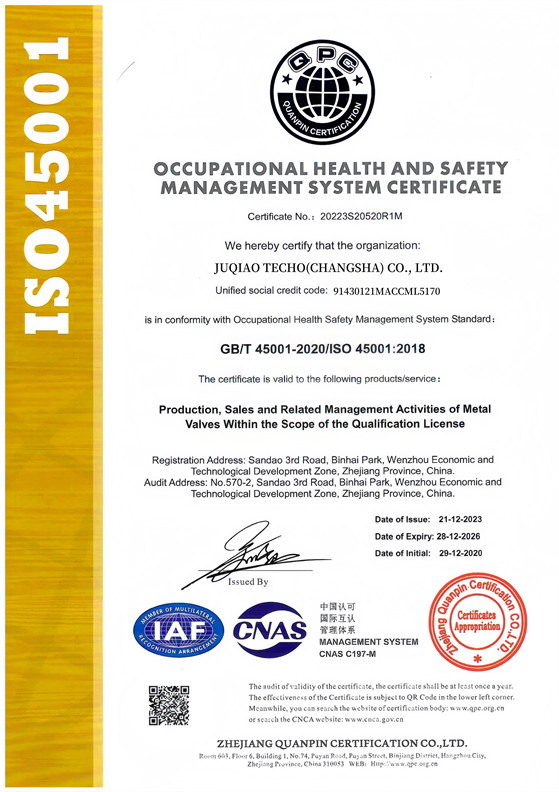

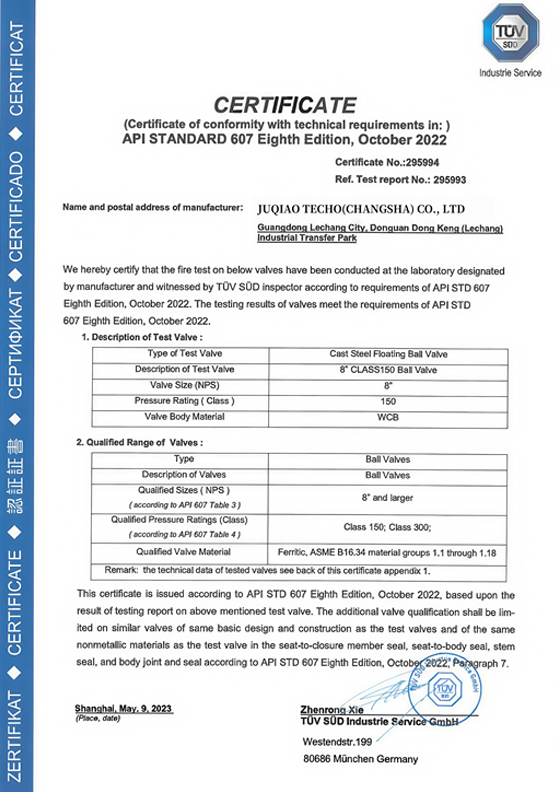

About Our Factory

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

Related Products

There is no relevant data for the time being, please add it backstage!