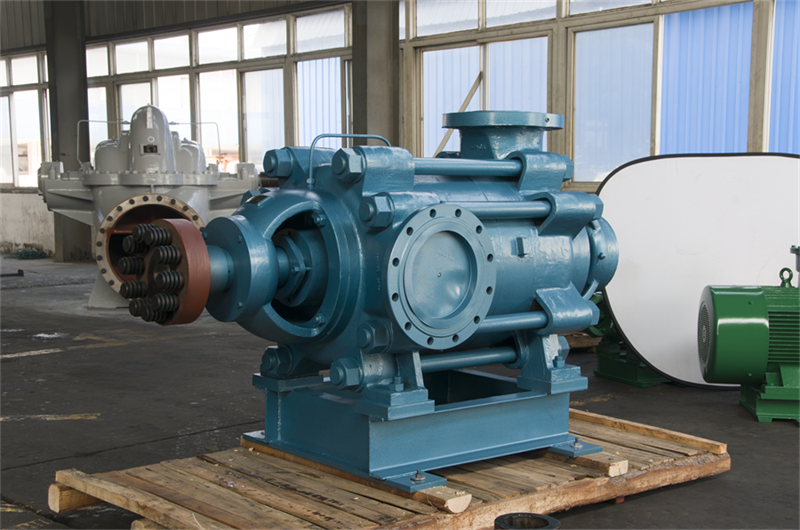

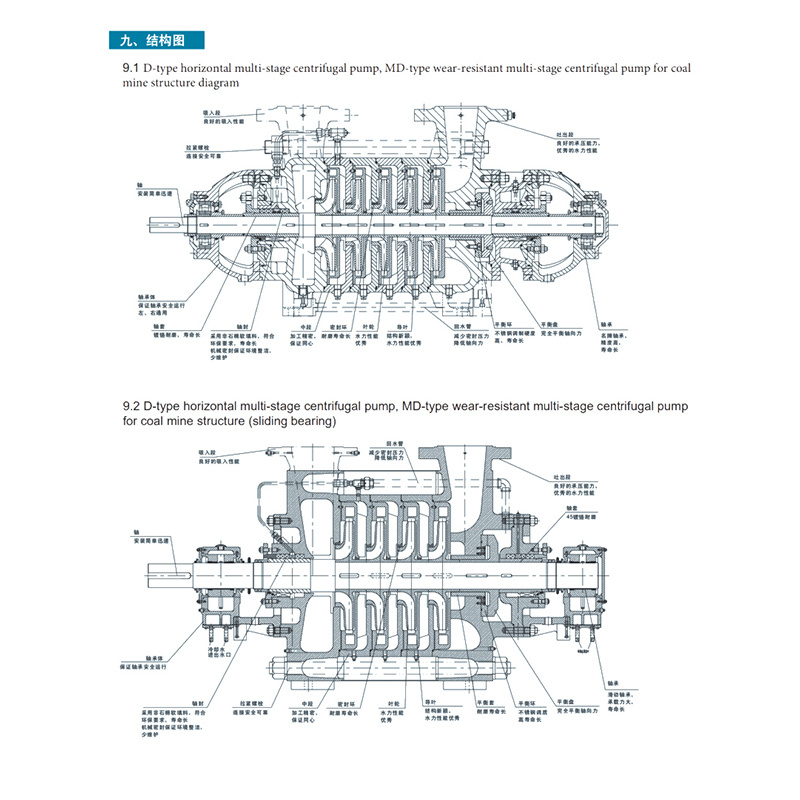

D&MD&DF Multi-Stage Centrifugal Pump

Flow: 3.75-1200 m3/h

Head: 50-1550m

Liquid temperature: 0-80℃

keyword:

Valve

D&MD&DF Multi-Stage Centrifugal Pump

Advantages of D/MD/DF:

·CFD flow field analysis technology optimization design brings high efficiency

·The static seal between the suction section, the middle section and the discharge section of the pump adopts metal seal and "O" ring double seal, and the pump shaft seal adopts high-performance ·ramie packing or mechanical seal, safe and reliable.

·Many different types of pumps can be chosen. They are suitable for most cases.

·The rotor adopts two balance processes, static and dynamic, and the beating of the rotor is strictly controlled, the pump operates stably and the vibration is small.

·The shaft is made of high-quality carbon steel, alloy steel or stainless steel through multiple heat treatment processes, with high rigidity and good stability.

·Adopting a unique shaft shoulder positioning structure, the impeller positioning is more reliable, and the operation is safer.

·The suction section and discharge section of the pump adopt high-quality castings or forgings, which ensure the reliability of product operation while ensuring hydraulic efficiency.

Suitable Applications:

D Horizontal Multi-Stage Centrifugal Pump, MD wear-resistant multi-stage centrifugal pump for coal mine and DF Corrosion-Resistant Multistage Centrifugal Pump. Because of using advanced technology and design, D/MD/DF have many advantages. They can be used in many different applications.

Working Parameters:

Rotating speed: 2960r/min

Flow: 3.75-1200 m3/h

Head: 50-1550m

Liquid temperature: 0-80℃

Previous

Next

FAQ

Product After-Sales Service

We provide 1 year after-sales service for our products, and can extend the after-sales service period for a fee as needed. Please feel free to inquire in detail.

About Customized Product Production

We support customized production needs for various valve products, including OEM&ODM, provided that there is legal authorization. Please contact our sales manager on our website for more information.

About Our Factory

We have factories in Hunan, Zhejiang, Guangdong, and Shanghai in China, which can meet the production of various valves.

Product Production Cycle

We have a strong production team that schedules production based on the number of product orders and production processes. For standard products, we can generally complete production within 7-30 days and support expedited production.

About Logistics

We cooperate with powerful international logistics companies, whether it is air or sea freight, and we can apply for the best transportation price for you because we have rich experience in international logistics transportation.

Related Products

There is no relevant data for the time being, please add it backstage!